Enterprise Culture

Our Phylosophy

Make core strategy for customers. Serve our customers is our important principal and their demands are our power to develop. Help customers to improve competitive power and profitable ability by providing quality machines, best service and faster innovation. Share trouble & interest with our customers to achieve win-win.

Our Perspective

Become a leading respectable company with more creative ability.

Our Value

Try our best to make you be satisfied & successful. Devote ourselves to making influential creation for you & us with high efficiency. Be honest and creditable. Make our decision and management to be correct & fiexible.

Our Mission

Supply competitive AUTO weighing and packaging system & keep bringing more benefits to you.

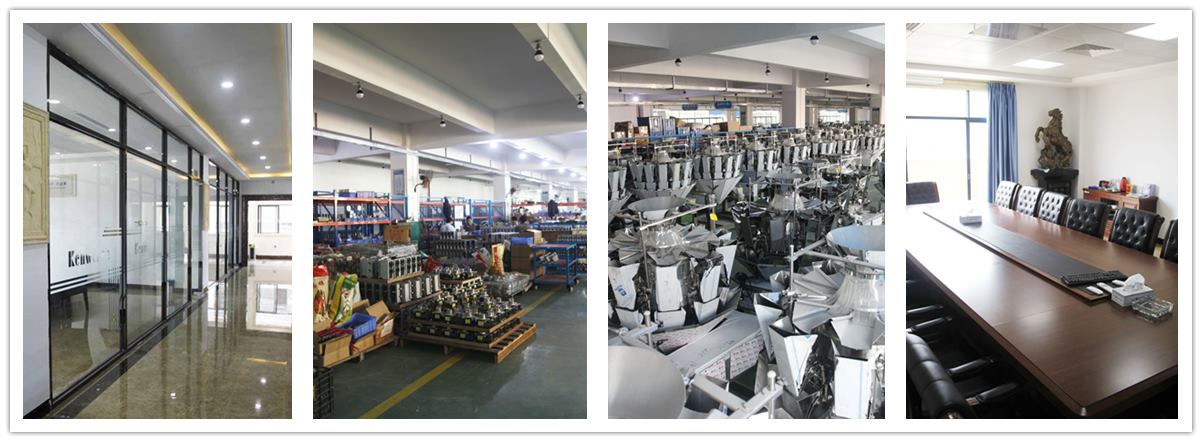

Guangdong Kenwei High Quality Achieves New Height of Precision

Strong Brand

Specialized in the production of automatic weighing and packaging machinery for 14 years, we devote ourself to the complete solution of automatic packaging. Now we become the professional multihead weigher (linear weigher/check weigher/metal detector etc ) manufacturing enterprise with large production capability and wide influence in the world. We have successively won the "Guangdong Industry-University-Research Science and Technology Project Award", "high technology enterprise" , "Technology Innovation Award" in Chinese food processing and packaging industry, Ringier Multihead Combination Weighing Technology Innovation Award, a number of "Utility Model Patent Certificate" and many other honorary certificates.

Craftsmanship products

Having high quality and R&D lab in the industry, our quality department covers 16 inspection points such as incoming materials checking, routing inspection, QE, pre-aging and post-aging inspection, finishing product inspection and a complete quality management system with restricted control of upper and lower processes. Our products passed the environment simulation test, frequency, waterproof test, salt spray test, amplitude and elastic stress-strain test, functional simulation test, 7*24 hours continuous aging test and so on. The core components such as circuit boards and touch screens are all passed for nonstop aging test for more than 72 hours at 50℃ environment because we devote ourself to manufacturing craftsmanship products with high quality. The failure rate of our products is less than 0.5% within 1 year and less than 1% within 2 years.

Optimal Accuracy

Kenwei independently researched and developed both standard and high amplitude vibrators. The vibration time and vibration amplitude of each vibrator can be automatically adjusted to optimize the material flow. Multi-head weigher central chassis is made from 2.5mm thickness stainless plate and strengthened structurally with internal strengthening rib. The AD conversion module combines technical modification with anti-interference technology to effectively minimize various vibration interference and ensure the accuracy of the whole machine.

Core Technology

Adopting the "stable time development model" which represents the highest level of multihead weigher field. It minimizes the interference factor of loadcell reading value caused by such as the different vibration, vibration torque of vibrators and hoppers, machine shaking due to the inconsistent stability time. It ensures the long-term stable operation of multihead weigher, at the same time maximizes the material saving.

Precision Parts

Adopting well-known Japanese and German brand load cells. Key components such as hoppers, linear pans, waterproof cover are made by high-precision molds, which contributes to a high consistency and interchange-ability. The circuit board design adopts the industrial grade design scheme, the industrial grade material and the manufacturing technology from the chip selection to the PCB design and the protection. The standard touch screens use LCD screen of 50,000-hours-life, which adopts the immunity standard higher than the EC general standard industrial environment, and achieves a high-level design of 4kV.

Professional Team

Having a high-quality team with more than 30% professional technicians, which ensures our comprehensive capacity from R&D, manufacturing, marketing, installation, technical training to after-sales service for complete automatic weighing packaging system.

Customized Requirements

According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on. Products are free to choose two kinds of modes combination of operation such as digital and modular, single outlet and multiple discharge outlet, high precision and high speed. Also we can develop software system independently to meet more customized requirements for customers.

Tailored Products

13 years experience in product customization and practical industry application. Special program technical team with rapid response. Tailored products and solution with high pertinence and applicability are delivered after the comprehensive planning and evaluation based on customer's actual production situation and usage.

Wide Application

Products have passed CE certificate, PA / MC certificate, OIML certificate and SGS enterprise qualification certificate, widely used in food, medicine, chemical, hardware, commodity fields. We reached strategic coope-ration with customers from more than 100 countries and regions around the world, and we will continue to create more economic benefits for our customers.