Introduction to the working principle and application scenarios of Kenwei’check weigher

Date:2022-12-26 16:37:00 Clicks:

The check weigher is mainly used to sort products into multiple grades by product weight and is widely used in online weight sorting in pharmaceutical, food, aquatic products, poultry, and other industries. It can directly replace manual weighing to achieve the purpose of improving production efficiency, improving accuracy, reducing labor, and reducing costs.

The working principle of the checking weigher: the weight detection and sorting of the check weighers are jointly completed by the weight sensor, AD module, PLC, and the sorting mechanism.

1、The weight sensor converts the weight information into an analog signal in the form of "voltage".

2、The AD module performs analog-to-digital conversion on the collected analog signal and converts it into corresponding weight data (that is, the real-time weight of the product on the weighing conveyor belt).

3、The PLC reads the real-time weight of the product from the AD module and calculates the weight of the product under test by analyzing and calculating all the weight data during the entire process of the product under test passing through the weighing conveyor belt.

At the same time, the PLC will judge the obtained weight Whether the data is within the required weight range, if it is not within the required weight range, the machine will start the belt reverse action, and reject the unqualified products.

Basic introduction

1、The machine is mainly used to check the weight of the packaged products during the conveying process. When the measured weight is unqualified, the belt moves in the opposite direction to remove it.

2、The machine is mainly suitable for soft and hard packaging products such as bulk paper bag packaging, plastic packaging, carton packaging, and metal film packaging.

3、The machine is in a stable working state and has the advantages of high speed and high precision.

4、Support LAN networking function; optional communication board can realize RS232 or RS485 serial communication.

5、Per-package weight data and production records can be exported via USB.

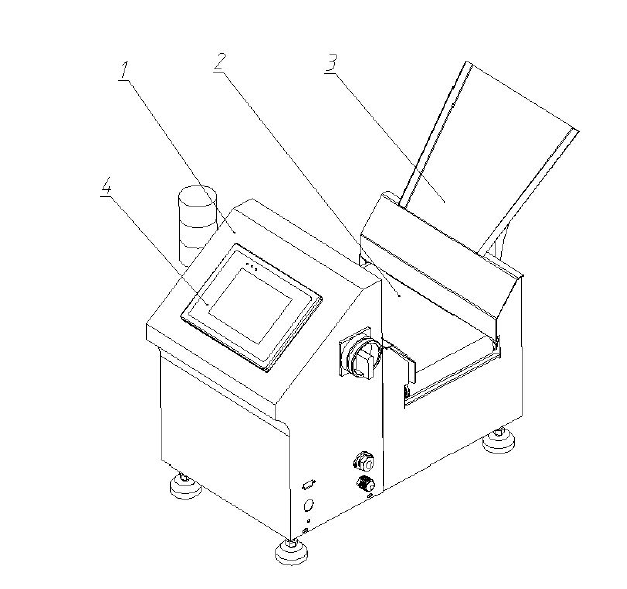

The basic structure of the sorting scale is shown in the figure, and the functions of each part are as follows:

1、Electric box: The electric box has a built-in PLC to analyze, calculate and process the collected weight data, and control the conveyor belt The action of the motor and the sorting mechanism.

2、Weighing belt: a weight sensor and an AD module are installed inside to collect weight data.

3、Material receiving plate: when the material falls, it buffers the impact force to the weighing belt and plays a guiding role at the same time.

4、Touch screen: The interface for the operator to interact with the machine.

Kenwei’s check weigher has the characteristics of fast inspection and detection, high measurement accuracy, and strong expansion performance, which provides a more economical solution for the inspection weighing operation on the production line.