JW-B23 Cup packaging and weighing System is suitable for weighing snack foods such as candy, melon seeds, jelly, frozen, pistachio, peanuts, nuts, almonds, raisins,etc, and is suitable for puffed food; hardware, plastic compounds and other granular, flaky, strip, round and irregular shape material.

1. High accuracy, applicable to filling to two cups in one mould, three cups in one mould, five cups in on mould, three cup in two mould, four cups in two mould, or five cups in two mould.

2. Fully automatic finishing whole process of feeding, weighing, filling bag, date printing,finished product output.

3. Applicable to a wide range of materials.

| Series model | Typical Machine | Speed | Max weight | |

| One divides into two cup packaging and weighing system | One set of 14 head multihead weigher | 80p/min | 800g | |

| One divides into three cup packaging and weighing system | One set of 14 head multihead weigher | 80p/min | 800g | |

| One divides into four cup packaging and weighing system | Two sets of 14 head multihead weigher | 140p/min | 800g | |

| One divides into five cup packaging and weighing system | Two sets of 14 head multihead weigher | 140p/min | 800g | |

| One divides into six cup packaging and weighing system | Two sets of 14 head multihead weigher | 140p/min | 800g | |

| One divides into eight cup packaging and weighing system | Four sets of 14 head multihead weigher | 280p/min | 800g | |

| One divides into ten cup packaging and weighing system | Four sets of 14 head multihead weigher | 280p/min | 800g | |

Reject unqualified products, it can sort the product and make statistics (if already equipped with other weight detection equipment then no need use this machine)

It is used to detect the metal which mixed during the production process. It is suitable to use after finishing packaging (if already equipped with other metal detector then no need use this machine).

It is used to detect the metal which mixed during the production process. It is suitable to use before packaging.It is installed between weigher and packaging machine,space saving (if already equipped with other metal detector then no need use this machine).

Metal detector combined with check weigher:

It is used to detect the metal and check weight,combined the check weigher with metal detector,save cost and less commissioning and maintenance time.

It is used to stuffing the small bag into the cup, like desiccant, the flavoring bag etc.

Capping after sealing the cup, the form of capping including capping alone or capping with add teaspoon and flavoring bag etc.

Label on the cup, the form of label including unilateral label, bilateral label etc.

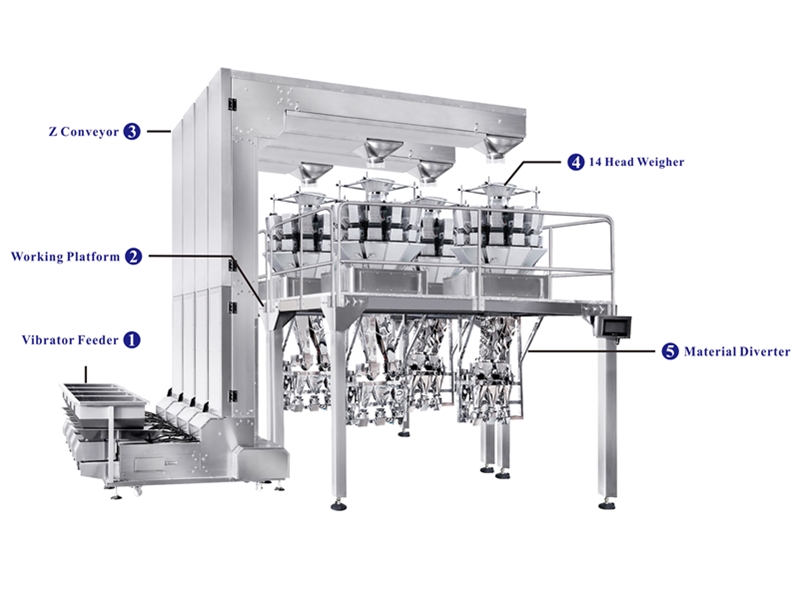

When need filling more than one cup in one time, then use this device. Such as, filling 2 cup in one time use one to two diverter, filling 4 cup in one time use one to four diverter.