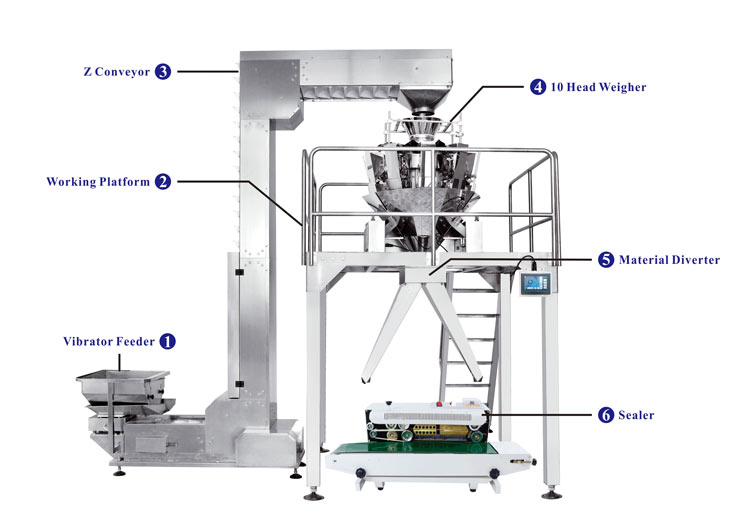

Two outlet semi auto weighing and packaging system is suitable for weighing powder and roll or regular shape granule, such as sugar, salt, seed, rice, sesame, glutamate, milk powder, coffee and season powder,etc.

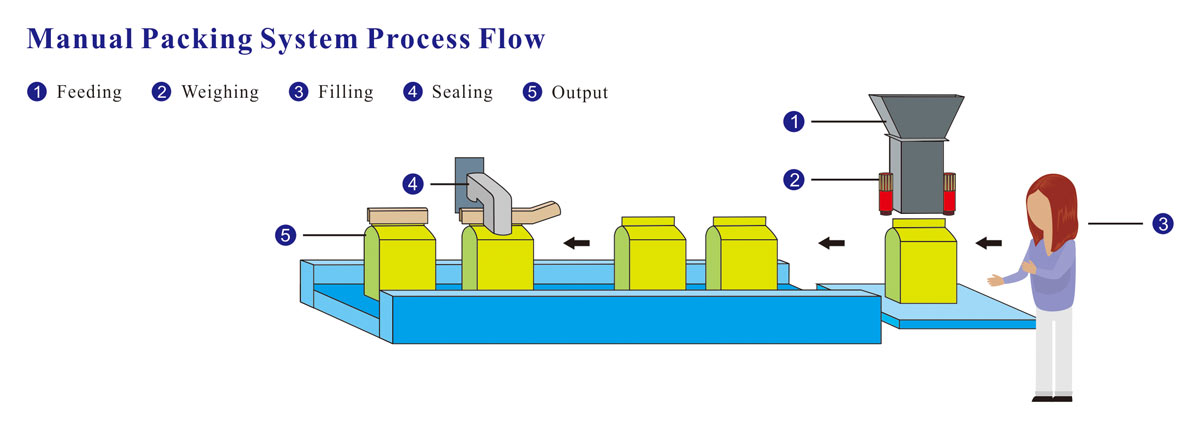

1. Fully-automatically completes all the process from feeding, weighing and finished products outputting;

2. Wide scope of application, Suitable for various materials, High weighing precision and efficiency.

3. Save space and input cost.

4. suitable for weighing powder and roll or regular shape granule.

5. cheapness, high price ratio, Suitable for kinds of bag type which cann’t made by packaging machine.

Used for check weight, and remove the unqualified products, classification and statistics of products.

Used for detect both magnetic and nonmagnetic metals which mixed in the products in the production process, suitable for detect after packaging.

Used for detect both magnetic and nonmagnetic metals which mixed in the products in the production process, suitable for detect before packaging, and fixed between the bottom of weigher and the top of VFFS feeding funnel, save space, but increase the hight of system.

Used for check the weight of products and detect the metal which mixed in the products, remove the unqualified products. It Combines check weigher and metal detector, save cost and the time of debugging and maintenance.

Used for convey the product to the next process.

1. Semi-auto weighing and packaging system(one output)

packaging speed 15-20p/min (Low speed, the multihead weigher is in a low load working state)

2. Semi-auto weighing and packaging system(two output)

Packaging speed 30-40p/min (need two person to collecting the product, the multihead weigher is in a normal load working state).

Process example: