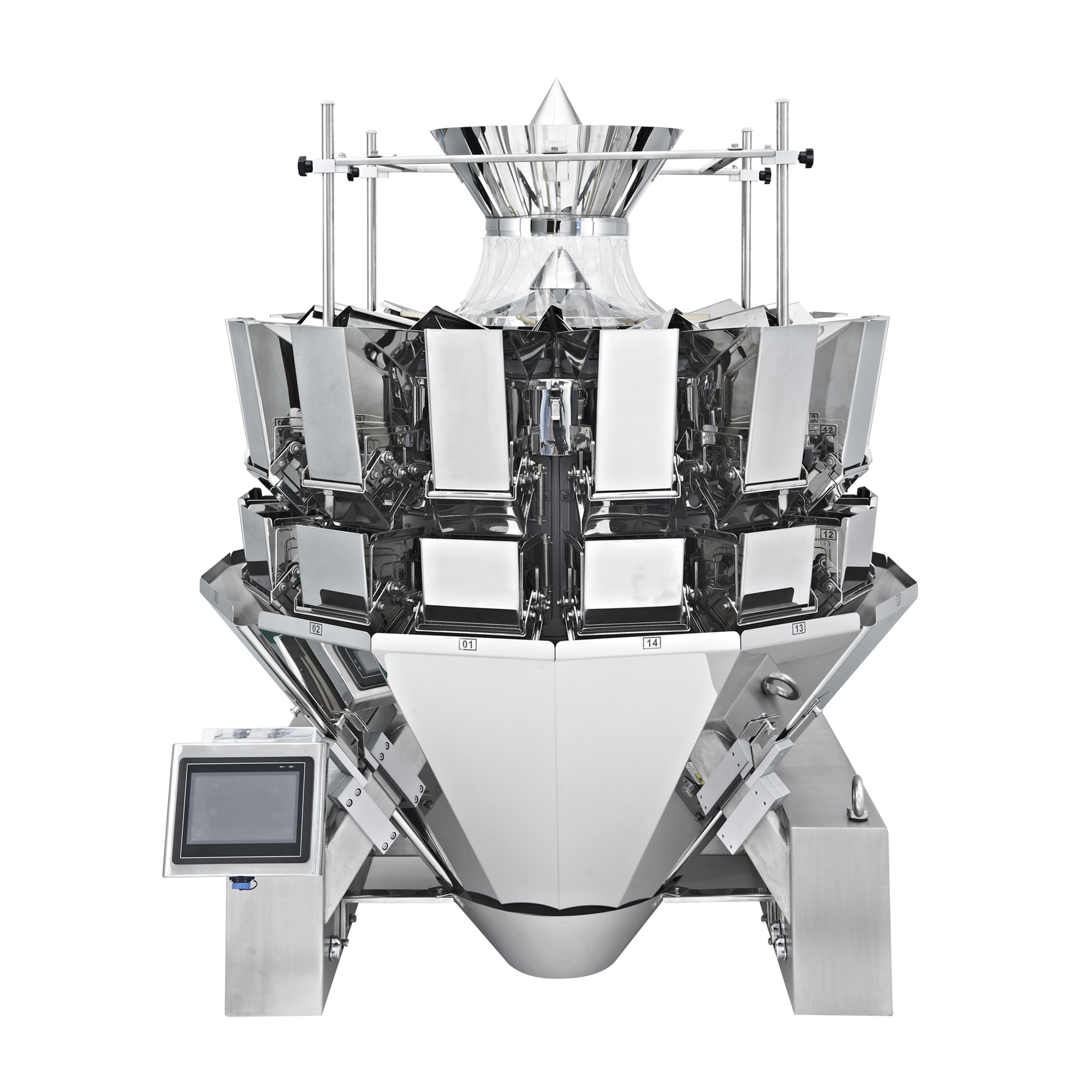

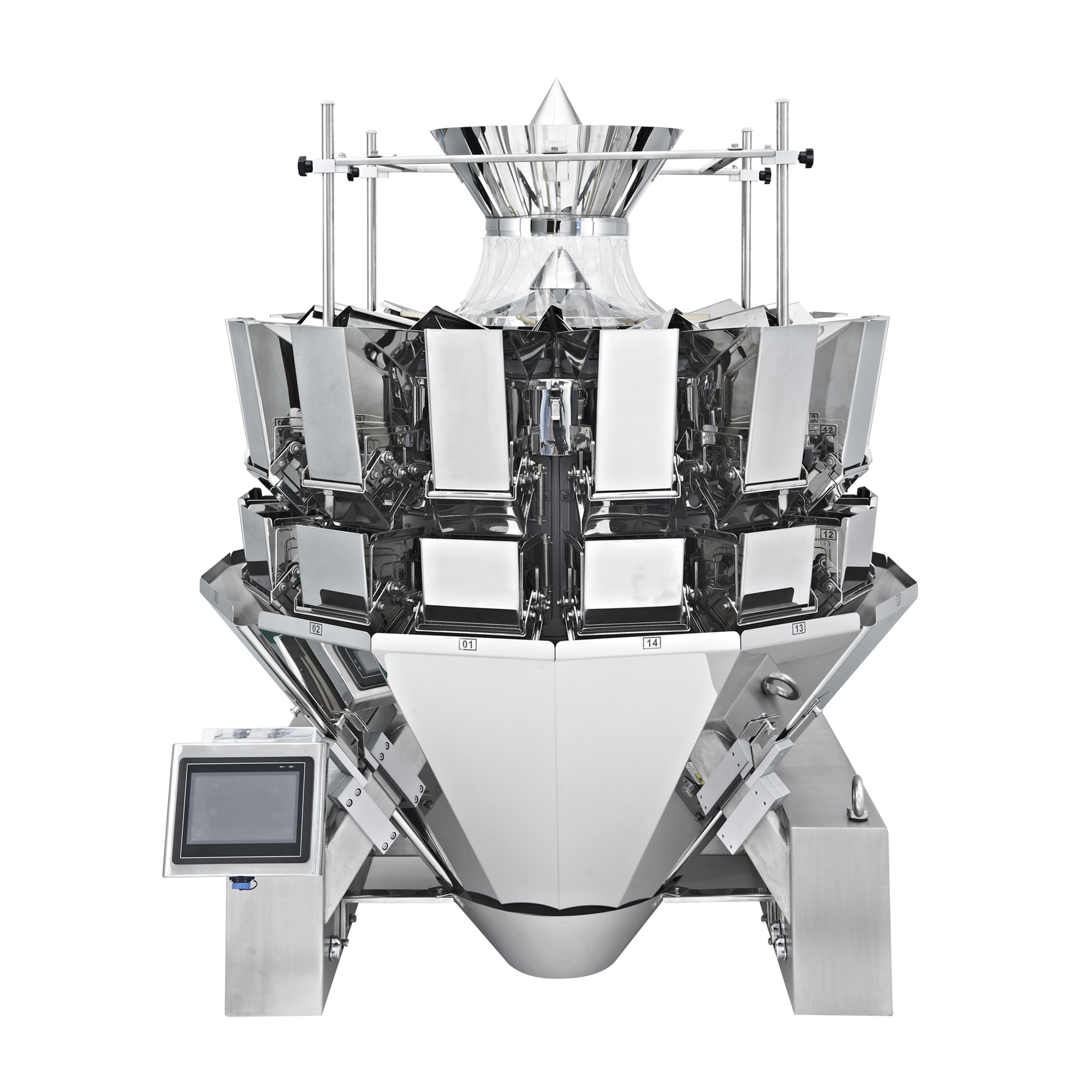

Counting multihead weigher is specially designed for counting projects, such as tea bags, coffee bags, cereal and soybean,milk powder, hardwares, plastic, etc.

1.Special load cell with high precision and high standard.

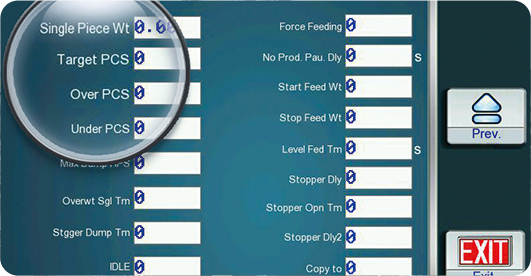

2.Program recovery function can reduce operation failures and support multi-segment weight calibration.

3.No products auto pause function can improve weighing stability and accuracy.

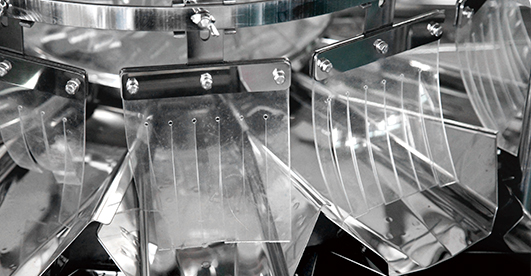

4.Linear amplitude can be adjusted independently.

5.Many languages available for global markets.

6.100 programs capacity can meet various weighing requirements and user-friendly help menu contributes to easy operation.

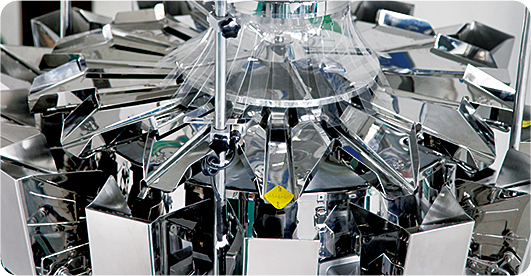

1.Unique and specially designed counting software, use no-divider discharge chute to avoids blocking problem.

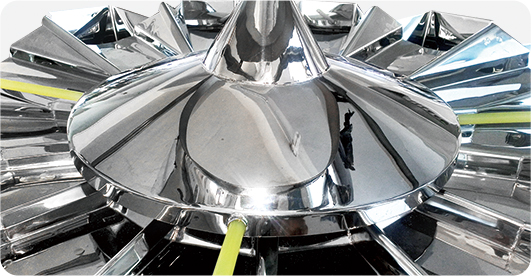

2.Equipped with a especially designed central cone, rotary top cone can dispense the products into each linear feeder pan evenly. Equipped with both weighing and counting softwares.

3.Weighing type for material detection makes accurate control of feeding time & material thickness and ensure weighing accuracy.

4.Mold making process and uniform design standards contribute to better interchangeability for spare parts.

5.Load cell detection under top cone ensures a smooth feeding process from conveyor and avoid blocking problem on top cone.

| Model | JW-A12 | JW-A14 |

| Identify Code | A12-1-2 | A14-1-2 |

| Weighing Range | 10-30PCS | 10-30PCS |

| Accuracy | X(0.5) | X(0.5) |

| Max Speed | 30P/M | 40P/M |

| Hopper Volume | 2.5L | |

| Control Panel | 7''Touch Screen | |

| Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

| Driving System | Step Motor | |

| Power Requirement | 220V/1000W/50/60Hz/10A | 220V/1500W/50/60Hz/10A |

| Packing Dimension(mm) | 1700(L)x1100(W)x1130(H) | 1700(L)x1100(W)x1265(H) |

| Gross Weight | 470kg | 490kg |