11 Multiple Units Multihead Weigher Mixing Weighing System JW-B28

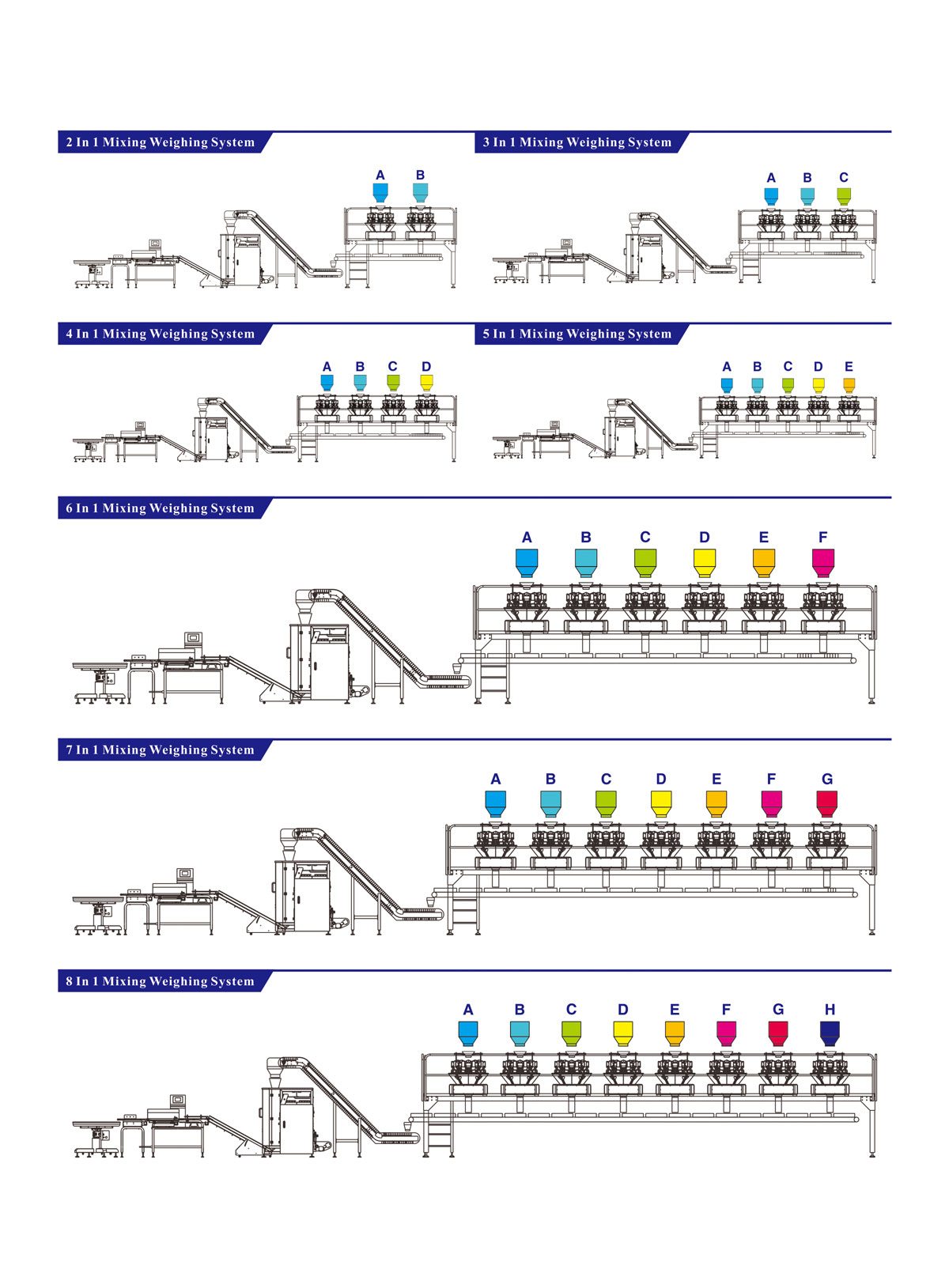

| System | Model | Max Speed | Max Capacity |

| 2 in 1 mixing weighing system | 2 units mini 10 head weigher | 60p/min | 400g |

| 3 in 1 mixing weighing system | 3 units mini 10 head weigher | 60p/min | 600g |

| 4 in 1 mixing weighing system | 4 units mini 10 head weigher | 60p/min | 800g |

| 5 in 1 mixing weighing system | 5 units mini 10 head weigher | 60p/min | 1000g |

| 6 in 1 mixing weighing system | 6 units mini 10 head weigher | 60p/min | 1200g |

| 7 in 1 mixing weighing system | 7 units mini 10 head weigher | 60p/min | 1400g |

| 8 in 1 mixing weighing system | 8 units mini 10 head weigher | 60p/min | 1600g |

Other Mixing Formula Weighing System can be customized

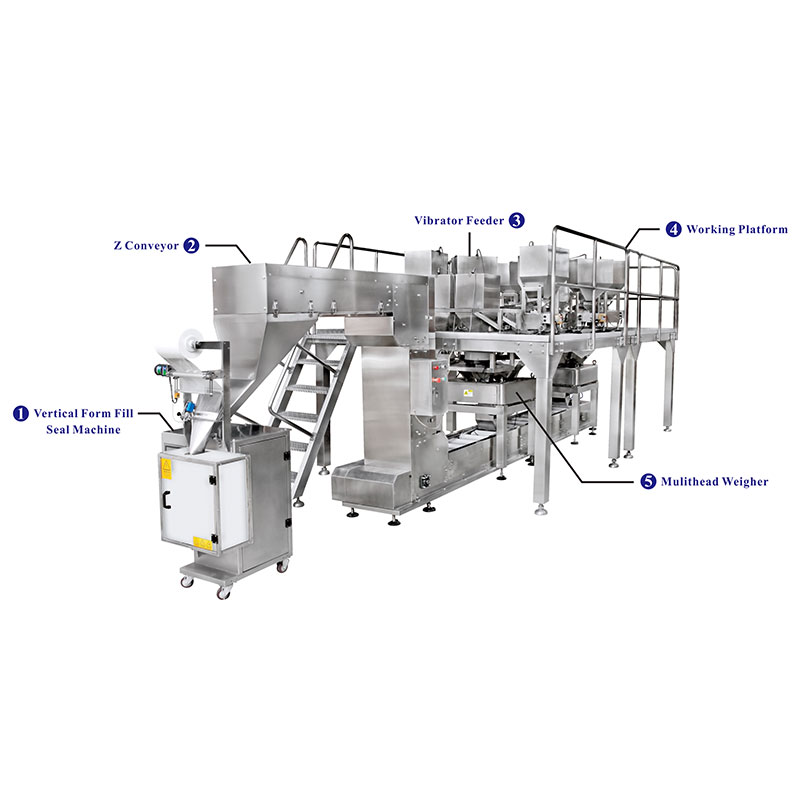

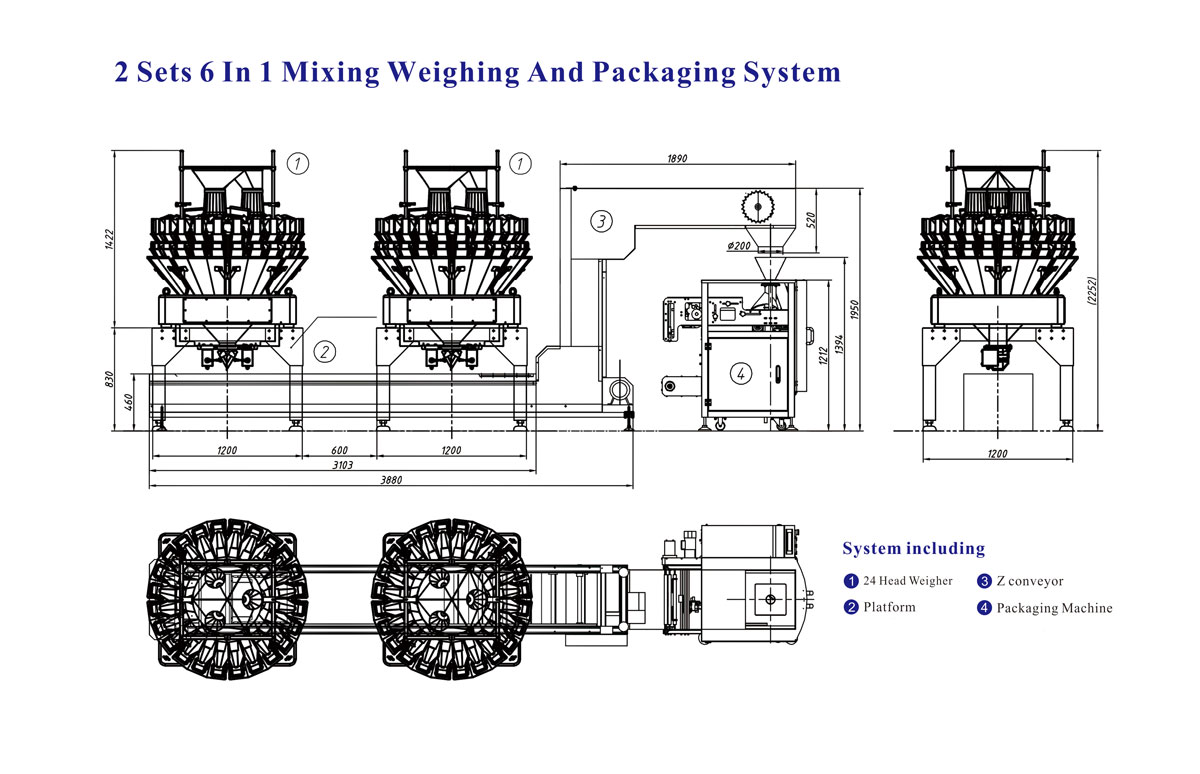

System including: Vibrator feeder, Z bucket conveyor, Working platform, Multihead weigher, Verticl form fill seal machine, Finished products conveyor, Dropper metal detector.

It is suitable for weighing granule, slice, roll or irregular shape products such as candy, seed, jelly, fries, coffee granule, peanut.puffy food, biscuit, chocolate, nut, pet food, frozen feeds, etc, It is also suitable for weighing small hardware and plastic components.

1. Fully automatic finishing whole process of feeding, weighing, filling bag, date printing,finished product output.

2. Mixing formula is in high accuracy with one motherboard operation controller which has complementary function, while ensuring the accuracy of the total weight.

3. Applicable to a wide range of materials.

Reject unqualified products, it can sort the product and make statistics (if already equipped with other weight detection equipment then no need use this machine)

It is used to detect the metal which mixed during the production process. It is suitable to use after finishing packaging (if already equipped with other metal detector then no need use this machine).

It is used to detect the metal which mixed during the production process. It is suitable to use before packaging.It is installed between weigher and packaging machine,space saving (if already equipped with other metal detector then no need use this machine).

It is used to detect the metal and check weight,combined the check weigher with metal detector,save cost and less commissioning and maintenance time.

Used to collect products from the production line,Suitable for production lines that require manual processing or waiting for further packaging operations.