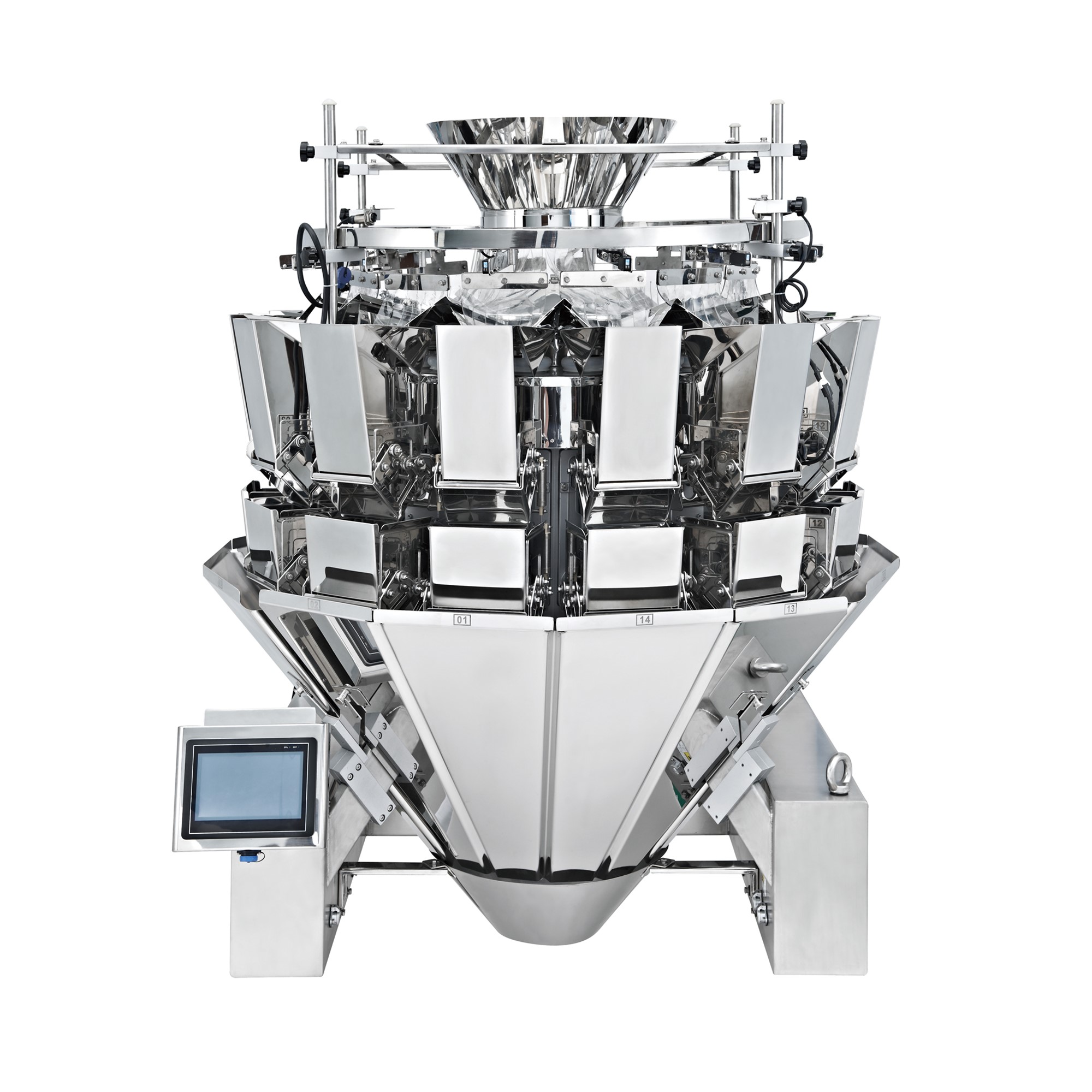

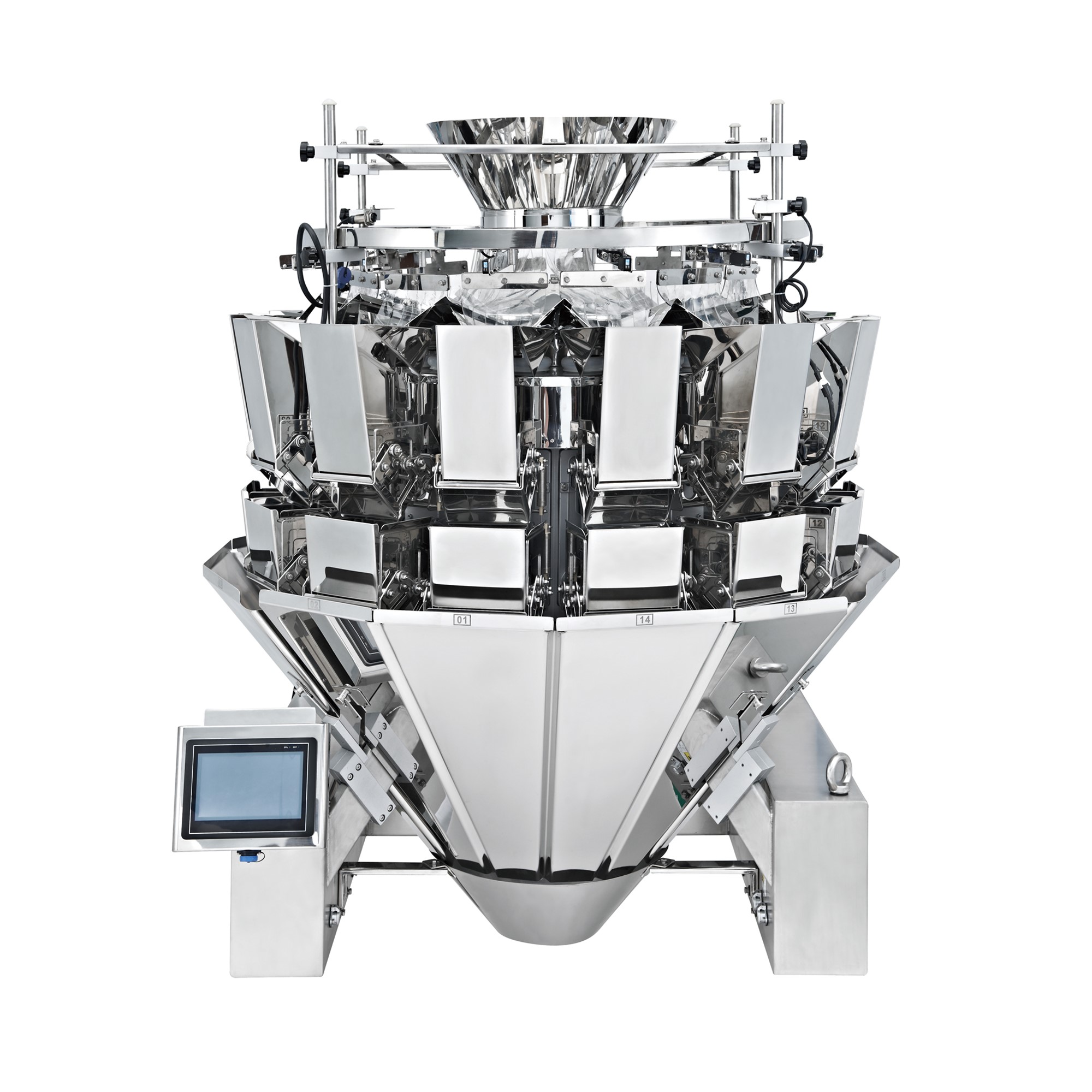

Feeding-control weigher is suitable for counting project, such as pepper, fruit, jelly, small packs, tomato, potato, onion, large-shell nuts, etc.

1.Special load cell with high precision and high standard.

2.Program recovery function can reduce operation failures, support multi-segment weight calibration.

3.No products auto pause function can improve weighing stability and accuracy.

4.Linear amplitude can be adjusted independently, can make the feeding more uniform.

5.15 languages available for global markets.

6.100 programs capacity can meet various weighing requirement, user-friendly help menu in touch screen contributes to easy operation.

1.Equipped with both weighing and counting softwares.

2.Vibration time is automatically adjusted to make sure a good feeding process and improve the combination possibility.

3.Extra MCU helps the motherboard CPU to judge and control the feeding process, effectively improve the weighing accuracy.

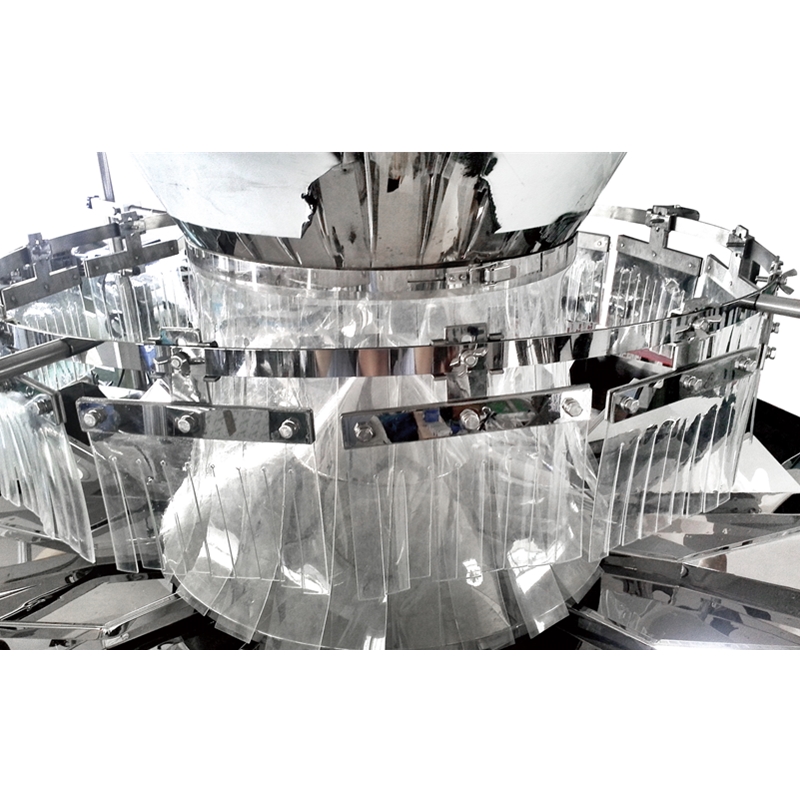

4.Wide V shape feeder pan with an independent photo sensor on its top, feeding process can be more uniform.

5.The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time.

6.Optional weighing type material detection, accurate control of feeding time, material thickness, to ensure the accuracy of the weighing.

| Model | JW-A10 | JW-A14 |

| Identify Code | A10-1-8 | A14-1-8 |

| Weighing Range | 10-1000g | 10-1500g |

| Accuracy | X(0.5) | X(0.5) |

| Max Speed | 30P/M | 60P/M |

| Hopper Volume | 1.6L/ 2.5L | |

| Control Panel | 7”Touch Screen | |

| Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

| Driving System | Step Motor | |

| Power Requirement | 220V/1000W/50/60Hz/10A | 220V/1500W/50/60Hz/12A |

| Packing Dimension(mm) | 1620(L)x1100(W)x1110(H) | 1700(L)x1100(W)x1265(H) |

| Gross Weight | 380kg | 490kg |