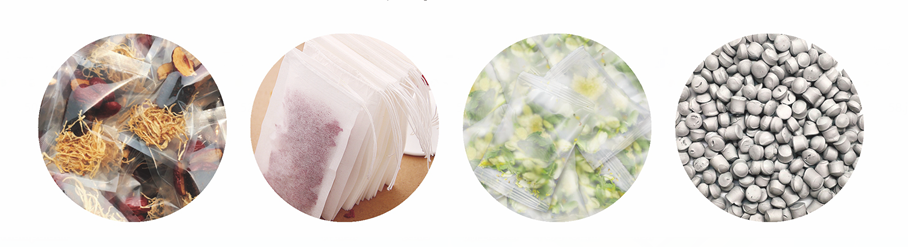

Parallel Manipulator is applicable to food, medicine, spices, plastics, handicrafts, electronics and various types of materials sorting and transporting of other industries .

1. It can be docked front-end check weigher, metal detector, X-ray detector and other packaging production line automation application equipment, strong versatility, wide application range, high precision and strong stability.

2. It can realize fast sorting ability and optional visual application system, which makes positioning more accurate and easier to grab.

3. Touch screen human-machine interface, multi-coordinate form debugging, jog control, parameter setting, etc., supporting teaching mode, complete linear, arc and space trajectory movement.

4. Teaching and debugging with teaching device, easy to learn programming, rich instruction set, can meet a wide range of application requirements, users can carry out secondary development.

5. Support multi-station appointments.

6. Overload automatic shutdown protection function.

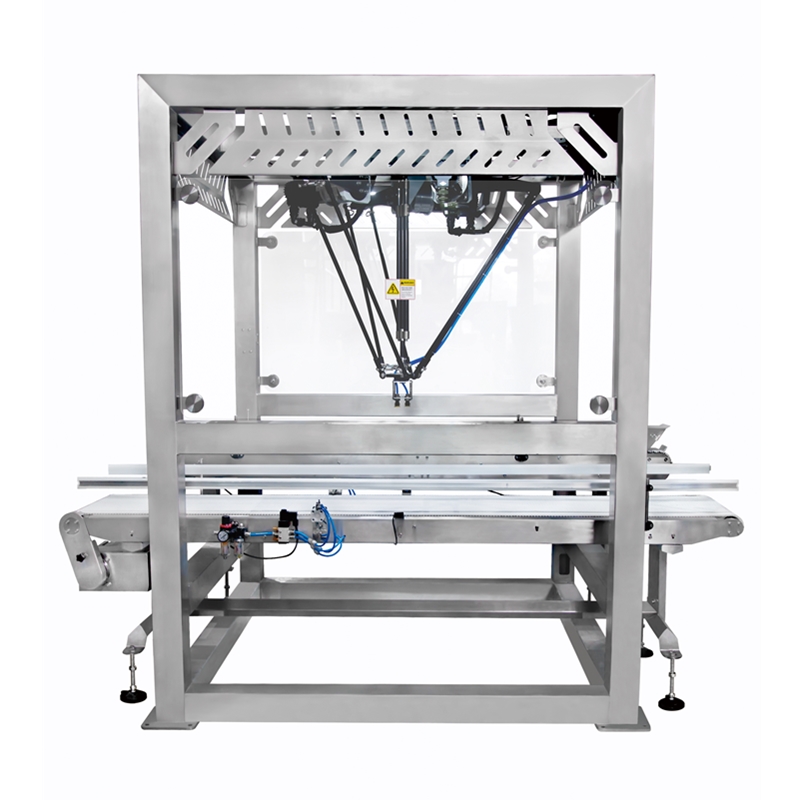

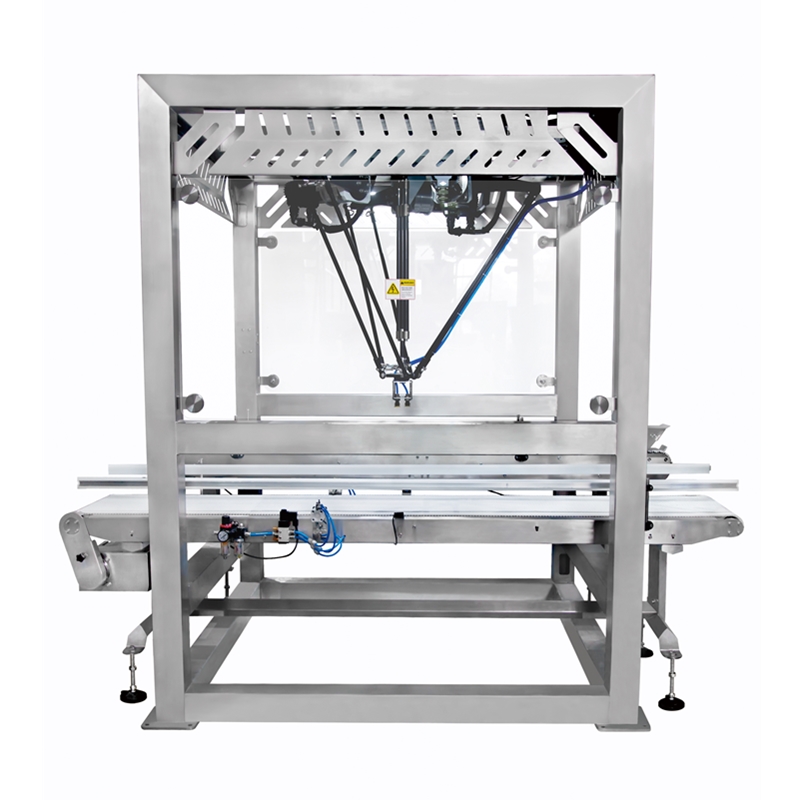

1. Independent main base with spraying, simple and beautiful appearance, easy to install and maintain.

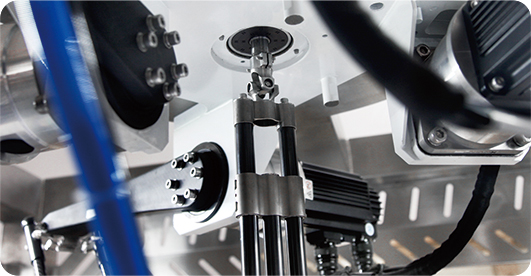

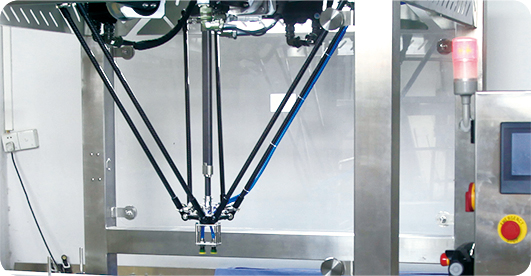

2. The rotating main arm is made of carbon fiber, which is lighter in structure and more stable in performance.

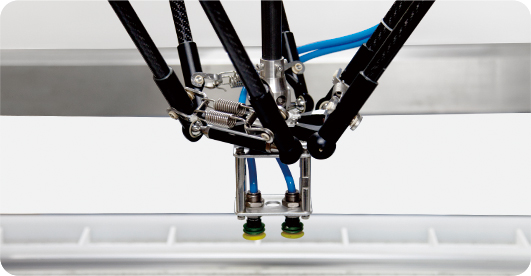

3. 4 Axis linkage structure, which can realize the material grabbing and rotating in the specified direction.

4. Use servo control system to ensure the accuracy of the work application.

5. Optional visual or telescopic and full-line conjoined applications, support for customized applications in the conveyor section, flexible configuration.

6. Optional body outer frame material according to the application environment, stainless steel / carbon steel are optional.

| Model | JW-D1100 |

| Identify Code | D1100-1-1 |

| Structure Type | DELTA(Four-axis parallel) |

| Repeat Accuracy | ±0.1mm |

| Working Range | φ1100mm |

| Max Speed | 150 P/M |

| Max load | 3000g |

| Power Requirement | 220V/4000W/50/60Hz/20A |

| Packing Dimension(mm) | 12000(L)x1100(W)x610(H) |

| Gross Weight | 110kg |